Static and Dynamic Pass Box classification

The main sources of cleanroom contamination are through equipment, Room structure and materials, improper ventilation, and the most important factor People. People ie. Personnel of a pharma factory are the largest sources of contamination in any pharmaceutical facility. It is for these reasons all major guidelines and regulatory bodies recommend using safe mechanisms of material transfer from one area ensuring Air- Borne contamination is controlled. This is the premise where Pass Boxes are the silent Heroes of any pharma facility.

Pass boxes play a verymajor role when it comes to Material transfer from an area of one classification to the other. They help avoid cross-contamination between two areas thereby maintaining the integrity of the cleanroom systems. The material used in construction of Pass boxes is SS304 or SS316 or SS316L. Some regions also refer to Pass boxes as Pass-Thru Hatches, Pass-through Windows, or Transfer Hatches. There are 2 basic types of pass boxes

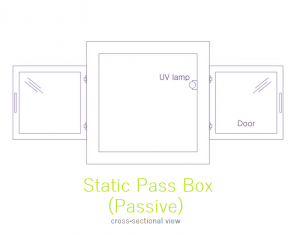

Static Pass box

• Fitted only between two cleanroom areas of the same classification levels and has no Ventilation ( air supply or extract) provision.

• It is also known as a passive pass box and is equipped with UV Light It’s mainly used for non-complex, quick transfers of products in the same classification of Air.

Dynamic Pass box

• Fitted between clean room areas of different classification levels and Material is passed through vertically HEPA filtered air.

• Also called Active Pass Box and they are too equipped with UV light

• If a Dynamic Passbox is fitted with a Vapourized Hydrogen Peroxide Generator ( VHP) as a decontamination system it may also be called a Bio De-Contamination Pass Box

Common characteristics in both types of Pass Boxes

Yes, the title speaks about the differences but we have to tell you the similarities first :

- Interlocked doors ( ensuring only door opens at a time)

- UV lights & Fluorescent / Visible lamps. ( yes there are two switches)

- These could be 2 door or 3 door pass boxes.

- UV light Hour meter ( the light switches off when either of the doors are open) these lamps are advised to be replaced after 3000 hours- Some would say 1000 )

- Completely Airtight.

- They can be Floor Mounted as well as Wall Mounted.

- Door Release Switch on either side.

- Internal Covings for easy cleaning.

- Both are cleaned with Disinfectants (70% IPA ) from time to time.